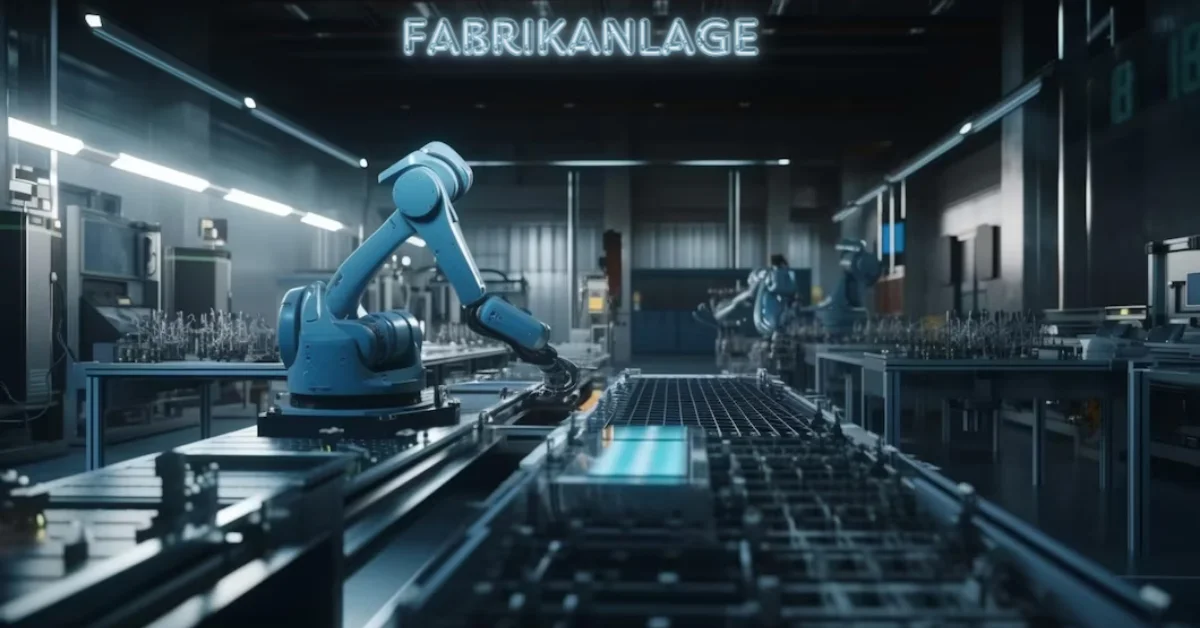

Fabrikanlage is a German word that means “factory layout” in English. When we talk about fabrikanlage, we are discussing how to design and arrange a factory in the best way possible. Good fabrikanlage helps make sure everything runs smoothly, from the machines to the workers.

Planning a fabrikanlage is like setting up a big puzzle. You need to think about where each piece goes to make sure everything fits perfectly. In this blog post, we will explore some easy tips and ideas for creating the best fabrikanlage for any factory.

What is Fabrikanlage?

Fabrikanlage means “factory layout” in English. It’s all about planning how a factory is set up. Imagine you have a big box of toys. If you put them in a messy way, it’s hard to find what you need. But if you arrange them neatly, you can easily find and use them. That’s what fabrikanlage does for a factory.

In a fabrikanlage, you decide where to place machines, storage, and workstations. This helps make sure everything runs smoothly. The goal is to make the factory safe and efficient for everyone working there.

A good fabrikanlage helps save time and money. When everything is in the right place, workers can do their jobs faster. They don’t have to walk too far or look too hard for what they need.

Why Good Fabrikanlage Matters

Good fabrikanlage is important because it helps keep a factory running smoothly. Imagine trying to build a big Lego set without a plan. It would be confusing and take forever. That’s why planning the layout of a factory is so important.

When a fabrikanlage is done well, it means workers can do their jobs better. They can find tools and materials easily, and there’s less chance of accidents. This means the factory works faster and is safer for everyone.

A good fabrikanlage also helps the factory save money. When everything is set up correctly, the factory uses less energy and materials. This helps keep costs down and makes the factory more efficient.

Basic Steps for Designing a Fabrikanlage

Designing a fabrikanlage starts with making a plan. First, think about what needs to go into the factory. This includes machines, storage spaces, and work areas. Make a list of everything you need and think about where it should go.

Next, draw a map of the factory. Put each item in the best spot so that workers can easily reach everything. The layout should be clear and simple, making it easy for everyone to move around.

After you have a plan, check it carefully. Make sure there is enough space for everything and that the factory will be safe. Sometimes, it’s helpful to get advice from experts to make sure the fabrikanlage is as good as it can be.

Key Elements of a Successful Fabrikanlage

A successful fabrikanlage includes several key elements. First, you need enough space for all the machines and workstations. If there isn’t enough room, it can make working in the factory difficult.

Another important element is the flow of materials and people. Everything should be placed so that workers can easily move from one part of the factory to another. This helps keep the work process smooth and efficient.

Safety is also a key element in fabrikanlage. Make sure there are safety signs and enough space for emergency exits. This helps keep everyone safe while they are working.

How to Plan the Layout for Your Fabrikanlage

Planning the layout for a fabrikanlage starts with understanding the factory’s needs. Think about what the factory makes and how workers will use the space. This helps decide where everything should go.

Draw a layout that includes all the machines, storage areas, and workstations. Make sure to leave space for people to move around easily. A good layout makes it easier for workers to do their jobs and helps keep everything organized.

Once you have a draft, check it carefully. Ask others for their opinions and make sure the layout works well. A well-planned fabrikanlage helps the factory run smoothly and keeps everyone happy.

Common Mistakes in Fabrikanlage and How to Avoid Them

One common mistake in fabrikanlage is not leaving enough space for workers to move around. If the factory is too crowded, it can be hard for people to do their jobs. To avoid this, make sure there is enough room between machines and workstations.

Another mistake is not planning for future changes. Factories often grow or change, so the layout should be flexible. Think about how the fabrikanlage might need to change over time and plan for it.

Finally, ignoring safety can be a big mistake. Make sure the layout includes safety features like clear exits and safety signs. This helps keep everyone in the factory safe and prevents accidents.

Tools and Software for Fabrikanlage Planning

There are many tools and software available for fabrikanlage planning. These tools help you create detailed and accurate layouts for a factory. They can show you how everything will fit together and help you make changes easily.

Software for fabrikanlage planning often includes features like drag-and-drop tools. This makes it easy to move machines and workstations around on the screen. You can see how different layouts will look and choose the best one.

Using these tools can save a lot of time and help you avoid mistakes. They make it easier to plan a fabrikanlage that works well and is efficient.

Examples of Great Fabrikanlage Designs

Great fabrikanlage designs often include smart layouts that make the best use of space. For example, some factories use a U-shaped layout. This design allows workers to move smoothly from one task to the next, which helps improve efficiency.

Another example is using modular designs. These designs make it easy to add or change parts of the factory layout as needed. This flexibility is important for factories that grow or change over time.

Looking at examples of successful fabrikanlage designs can give you ideas for your own factory. See what works well in other factories and think about how you can use similar ideas.

Tips for Improving Your Existing Fabrikanlage

Improving your existing fabrikanlage starts with looking at what works and what doesn’t. Check if there are any areas where space is wasted or where workers have trouble moving around.

One tip is to reorganize the layout to make it more efficient. Move machines and workstations to better locations to improve the flow of work. This can help save time and make the factory run more smoothly.

Another tip is to get feedback from workers. They can tell you what changes would help them do their jobs better. Making small changes based on their feedback can have a big impact on the factory’s efficiency.

Fabrikanlage: The Role of Safety in Factory Layouts

Safety is a crucial part of fabrikanlage. A good factory layout includes features that help keep workers safe. This means having clear paths for moving around and making sure there are enough exits in case of an emergency.

Another safety feature is proper placement of safety equipment. This includes things like fire extinguishers and first aid kits. They should be easy to reach and located in places where they are most needed.

By including safety in your fabrikanlage design, you help prevent accidents and keep everyone in the factory safe. This makes for a better and more productive working environment.

How Fabrikanlage Affects Worker Efficiency

The fabrikanlage design has a big effect on how efficiently workers can do their jobs. If the layout is well-planned, workers can move easily from one task to another. This helps them work faster and get more done.

Good fabrikanlage also means workers have everything they need close by. When tools and materials are easy to reach, workers don’t waste time looking for them. This helps keep the work process smooth and efficient.

In contrast, a poorly planned fabrikanlage can slow down work and cause frustration. Making sure the layout supports the workers’ needs helps improve their efficiency and overall job satisfaction.

Future Trends in Fabrikanlage Design

Fabrikanlage design is always changing to keep up with new technology and ideas. One future trend is the use of smart technology in factory layouts. This includes using sensors and automation to make factories more efficient.

Another trend is designing factories to be more flexible. This means creating layouts that can easily change as the factory’s needs change. This helps factories adapt quickly to new products or processes.

Keeping up with these trends can help you create a fabrikanlage that is modern and efficient. Looking at future trends can give you ideas for designing a factory that will work well now and in the future.

Benefits of an Efficient Fabrikanlage

An efficient fabrikanlage brings many benefits to a factory. First, it helps save time. When machines and workstations are well-placed, workers can easily move from one task to another. This means they can complete their work faster and more effectively.

Another benefit is cost savings. A good layout reduces wasted space and helps use resources more effectively. This can lower the factory’s expenses and increase overall profitability.

Moreover, an efficient fabrikanlage can improve worker satisfaction. When everything is organized and easy to access, workers have a better experience. They can focus more on their tasks and less on searching for tools or materials.

How to Evaluate a Fabrikanlage

To evaluate a fabrikanlage, start by examining the current layout. Look at how well the factory operates and if there are any issues. For example, are there any bottlenecks where work slows down? Are there areas where workers struggle to move around?

Next, gather feedback from the workers. They can provide valuable insights into how the layout affects their daily tasks. Ask them about any difficulties they face and what improvements they suggest.

Finally, compare the current fabrikanlage with best practices and industry standards. This helps identify areas where the layout might fall short and how it can be improved to match successful factory designs.

The Importance of Flexibility in Fabrikanlage

Flexibility is a key aspect of fabrikanlage design. Factories often need to change their layout as their needs evolve. For instance, new products or technologies may require different machine placements or work areas.

A flexible fabrikanlage allows for easy adjustments. Modular designs, for example, can be reconfigured as needed. This adaptability helps the factory stay competitive and respond to new opportunities or challenges.

Designing with flexibility in mind also helps future-proof the factory. As industry trends change, a flexible layout can quickly accommodate new processes or equipment without major disruptions.

Integrating Technology in Fabrikanlage Design

Technology plays a big role in modern fabrikanlage design. Advanced software tools can help create detailed and accurate layouts. These tools often include features like 3D modeling and simulations to visualize how different setups will work.

Automation is another technological advancement used in fabrikanlage design. Automated systems can help streamline operations, reduce human error, and increase efficiency. For example, automated conveyor belts can move materials quickly and accurately.

Integrating these technologies into the fabrikanlage helps make the factory more efficient and modern. It ensures that the factory can handle complex processes and meet high production standards.

Designing for Sustainable Fabrikanlage

Sustainability is an important consideration in fabrikanlage design. A sustainable factory layout helps reduce the environmental impact of operations. This can include using energy-efficient machines and minimizing waste.

Designing for sustainability also involves optimizing resource use. For instance, planning the layout to minimize energy consumption and recycling materials can make the factory more eco-friendly.

Incorporating green practices into fabrikanlage design not only benefits the environment but also can lead to cost savings. Sustainable practices often result in lower utility bills and reduced waste disposal costs.

Challenges in Fabrikanlage Planning

Planning a fabrikanlage comes with several challenges. One major challenge is balancing the needs of different departments. Each area of the factory might have specific requirements, and it can be tricky to meet them all while keeping the layout efficient.

Another challenge is dealing with limited space. Factories often have to make the most of the available area. This requires creative planning to fit everything needed without overcrowding the space.

Ensuring safety is also a challenge. The layout must include safety features and comply with regulations. It’s important to plan for things like emergency exits and safe work areas to prevent accidents.

Impact of Fabrikanlage on Product Quality

The fabrikanlage design can significantly affect product quality. A well-designed layout ensures that production processes run smoothly and consistently. This helps maintain high standards and reduces the chance of defects.

For example, placing quality control stations in key areas of the factory can help catch issues early. This means problems can be addressed before they affect the final product.

A good fabrikanlage also helps ensure that materials and equipment are properly maintained. Regular maintenance can prevent breakdowns and ensure that products meet quality standards.

Role of Ergonomics in Fabrikanlage Design

Ergonomics plays an important role in fabrikanlage design. It involves designing workspaces that fit the needs of workers. This helps reduce strain and improve comfort, which can lead to better performance.

For instance, adjustable workstations and ergonomic tools can make tasks easier and less tiring. This helps prevent injuries and keeps workers healthy.

Including ergonomics in fabrikanlage design also boosts productivity. When workers are comfortable and their needs are met, they can work more efficiently and effectively.

Collaboration in Fabrikanlage Design

Collaboration is key in designing an effective fabrikanlage. Different teams, such as engineers, architects, and managers, need to work together to create the best layout. Each team brings unique insights and expertise to the planning process.

Involving workers in the design process is also important. They have first-hand experience with the factory layout and can provide valuable feedback on how to improve it.

Effective communication and teamwork help ensure that the fabrikanlage meets all needs and works well for everyone involved. Collaboration leads to a better design and a more successful factory setup.

Assessing the Cost of Fabrikanlage Changes

Changing a fabrikanlage can involve significant costs. It’s important to assess these costs before making any changes. This includes looking at expenses for new equipment, construction, and any downtime during the transition.

Calculating the return on investment (ROI) is also crucial. This involves comparing the costs of changes with the potential benefits, such as increased efficiency and reduced operating costs.

By carefully assessing the costs and benefits, you can make informed decisions about fabrikanlage changes. This helps ensure that any updates lead to improvements and are worth the investment.

Training Workers for New Fabrikanlage Setups

When a fabrikanlage is changed or updated, training workers is essential. They need to understand the new layout and how to work with any new equipment or processes. Proper training helps ensure a smooth transition and avoids confusion.

Training should include hands-on practice and clear instructions. Workers should be familiar with the new layout, safety procedures, and any changes in their tasks.

Effective training also helps maintain productivity. When workers are well-prepared for the new fabrikanlage, they can adapt quickly and continue working efficiently.

Measuring the Success of Fabrikanlage Improvements

To measure the success of fabrikanlage improvements, start by setting clear goals. These could include increasing efficiency, reducing costs, or improving worker satisfaction.

Next, collect data before and after the changes. This helps you see how well the new layout is working and whether it meets your goals. For example, track production rates, cost savings, and feedback from workers.

Regularly reviewing this data helps determine if further adjustments are needed. By measuring success, you can ensure that your fabrikanlage improvements lead to real, positive changes.

Conclusion

In conclusion, a well-planned fabrikanlage is key to running a successful factory. It helps organize machines and work areas so everything runs smoothly and efficiently. When the layout is right, workers can do their jobs faster, and the factory can produce more with less effort.

Remember, a good fabrikanlage design also keeps everyone safe and happy. It saves time and money, making the factory a better place to work. By carefully planning and regularly updating the fabrikanlage, factories can stay efficient and meet their goals.

Leave a Reply